De-Spoolers

Utilising state of the art technology

- List Item 1

Let us supply you with the right packaging

De-Spooling Specialists

Utilising state of the art technology, SJA can produce spools and pads from a wide variety of materials on both 12 and 24 head spooling machines.

These machines have the range and flexibility to enable SJA to consistently meet the needs and expectations of customers from different industries and, in many instances, revolutionise their production throughput.

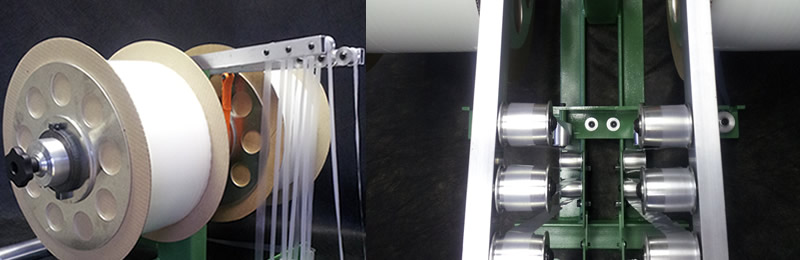

Machines using traditional pads of around 2,500 metres can be converted to use spools of 20,000m giving an enormous reduction in downtime previously caused by reel changes.

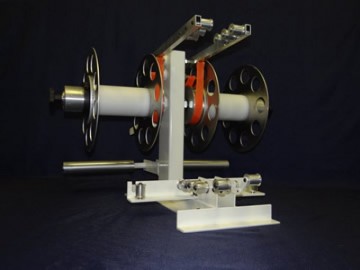

Where spools replace pads they need to be unwound for the customers’ production process and this can now be easily achieved utilising cost effective single or double-head De-Spooling units built by SJA Film Technologies. These units not only allow the film to unwind in a straight line they also control the unwind tension allowing for greater precision in the final process.

When spools are used in conjunction with these user-friendly De-Spooling Units customers can achieve huge savings because of reductions in both downtime and scrap.

Other Products

If you can’t find the service or product that you are looking for on this page, why not take a look at some of the other products that we supply at SJA Film Technologies below!

Silicone Release Liners

Silicone Release Liners

Click HereSpooled Products

Spooled Products

Click HereTrade Services

Trade Services

Click HerePackaging Films & Papers

Packaging Films & Papers

Click HereNeed Advice? Request a call back today!

If you would like to speak to a dedicated member of the SJA Film Technologies team about the services that we offer in more detail, simply provide us with a few quick details by completing the form below and contact our team today!