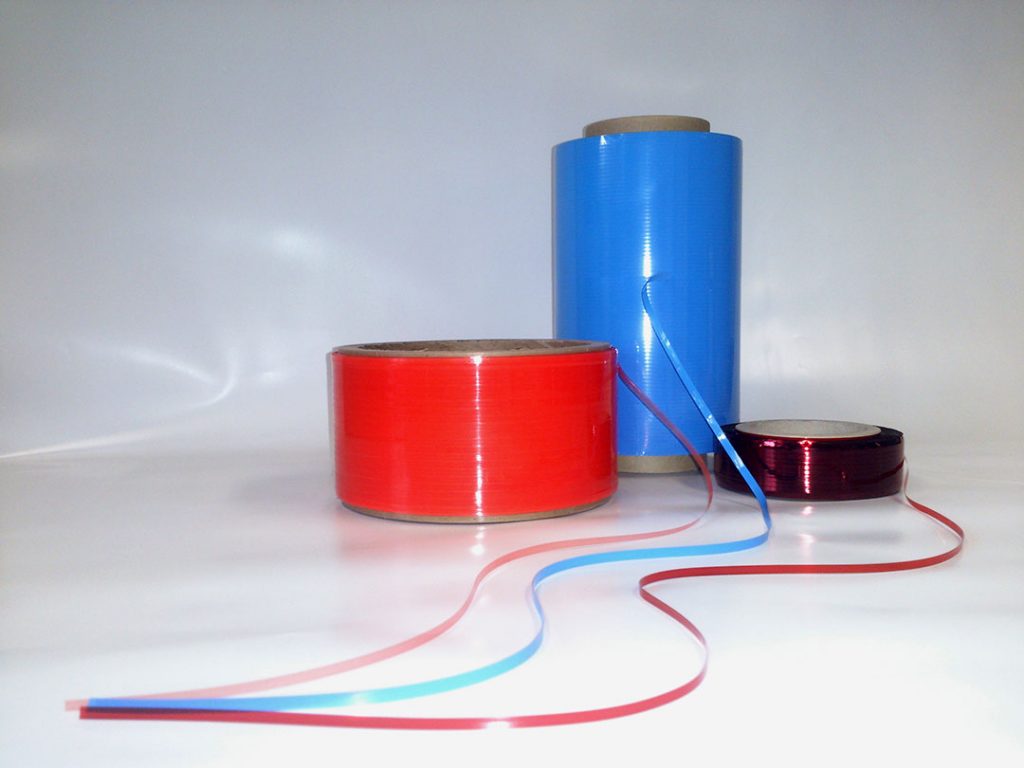

Traverse Wound Bobbins - Spools

SJA Film Technologies are one of the leaders in UK spooling technology.

- List Item 1

Let us supply you with the right packaging

We currently have state of the art 12 head and two 24 head traverse wound bobbin machines on site. Both machines can convert extensible / non extensible, adhesive / non adhesive substrates from 3mm through to 34mm width. This technique gives the converter the advantage to change from conventional pancakes (pads) to a bobbin.

Please see Trade Traverse wound bobbins – Spools page for our spooler capabilities

Changeover times are made irrelevant by moving from pads (pancakes) to bobbins. Efficiencies can increase significantly, and, waste reduces dramatically.

Please see below an estimate in time and scrap savings.

To assist in the transition of pads to bobbins, we can supply various de-spooling equipment that can take the bobbin to a take-off point which enables the tape to be fed straight into the relevant conversion machine.

This de-spooling equipment eradicates the uncertainty surrounding changing from pads to bobbins.

Save time, reduce waste, and increase profitability

Example of how much time / scrap can be saved when using spools with our de-spooling units against the normal of running single wound pads.

Example – Where 20,000m spools replace 2,500m pads

Downtime

- Spool changeover 2 minutes – 1 spool per working day and 250 working days per annum

- 250 x 2 minutes – 500 minutes – 8 hours 20 minutes per annum for an operator

- Pad changeover 2 minutes – 8 pads per working day and 250 working days per annum

- 8 x 250 x 2 minutes downtime.

- 66hrs 40 minutes per annum or 1.67 working weeks saved per operator!

Scrap

- 50m lost at end of each spool – 250 spools per annum – 12,500m lost each year

- 50m lost at end of each pad – 2000 pads per annum – 100,000m lost each year

Save time. Reduce waste. Increase profitability

Products converted to date

5 microns though to 5mm (dependant on substrate):

- Filmic Substrates – PET, OPP, CPP etc

- Security Tapes and Identification tapes

- Silicone Release Liners (Filmic and paper)

- MET PET

- ALUPET (Aluminium/Polyester)

- Holographic Film

- Foam

- Paper

- Hot Stamping Foil

- Non-woven Tapes

- Adhesive Labels, Tapes & Foils

Similar Products

The expert team here at SJA Film Technologies provide many products that help our clients fulfill their packaging requirements. Check out some of the most well-favoured products that we can manufacture below.

Silicone Release Liners

Silicone Release Liners

Click HereSpooled Products

Spooled Products

Click HereTrade Services

Trade Services

Click HerePackaging Films & Papers

Packaging Films & Papers

Click HereNeed Advice? Request a call back today!

If you would like to speak to a dedicated member of the SJA Film Technologies team about the services that we offer in more detail, simply provide us with a few quick details by completing the form below and contact our team today!